A major element of Kilomentor’s philosophy of

organic synthesis and chemical process development is to recommend developing

processes that have as preferred process intermediates compounds that are

sufficiently acidic or basic that they can be separated and purified by

acid-base extraction or which can be readily crystallized in salt form.

In further examining the latter aspect, an important

question is what salt of amines, in general, is most likely to be insoluble in

water. Presented with a previously

unknown amine-free base and asked to prepare a solid salt that can be readily

purified, is there any salt that is more likely to be made successfully on the

first attempt? Although modern chemists

realize that any relationship between molecular structure and physical

properties is tenuous, Kilomentor is convinced that the pamoate is that salt.

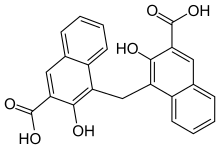

The acid, alternately called pamoic acid, embonic

acid or methylene-bis-1-(2-hydroxy-3-naphthoic acid was first described by

Hosaeus in 1892! In 1929, I.G.

Farbenindustrie A.G. patented a method for manufacturing sparingly soluble, tasteless salts of nitrogenous basic compounds, in particular salts of

alkaloids such as quinine and strychnine, and of bases of the ‘plasmochin’ type, using embonic acid. In 1946, a US patent US 2,397,903 was issued, claiming a

methylene-bis-2-hydroxy-3-naphthoic acid salt of a compound of the class

consisting of thiamine and pyridoxine.

From the very beginning of its application in

chemistry the substance called embonic or pamoic acid was used to prepare water

insoluble salts of amines, particularly amines that have two basic functional

groups.

Pamoate is a pharmaceutically acceptable

salt. Thus, trace residues are not

problematic in drug synthesis. Pamoates have been used frequently to make drug

products. It is almost

exclusively used to make modified release formulations that draw out the active

substance’s delivery into the bloodstream of a patient and so provide a long-lasting medical effect. This extended release relies on the poor relative solubility of pamoate salts in digestive fluids.

Pamoic acid is commercially available but its

synthesis is also simple and inexpensive. The procedure were provided by Barbier

and Gaimster in J. Appl. Chem., 2, October 1952. Since this old reference is probably stored

in an off-site warehouse even in one of the best libraries, Kilomentor is

reproducing the synthesis procedures below:

“Method I.

2-hydroxy-3-naphthoic acid (750 g.) was

suspended in glacial acetic acid 97.5 l.) and stirred at 95-100 C until

dissolved. A mixture of glacial acetic acid (750 g.), 40% formaldehyde solution

(450 g.) and concentrated sulfuric acid (71 g.) was added over 20 minutes, the

reaction being sufficiently exothermic to maintain the temperature between 95

and 100 C. The suspension of embonic

acid was stirred at 95-100 C for 30 minutes, allowed to cool to 70 C, filtered

and washed first with hot glacial acetic acid 94.5 l. and then distilled water

until the washings were no longer acidic to Congo red. The material was dried

at 100 C to give embonic acid (700 g.).

Method II.

2-hydroxy-3-naphthoic acid (500 g.) and

10% sodium hydroxide (1500 ml.) was heated to 90 C with stirring; about two

thirds of the solid dissolved. 40% formaldehyde solution (63 g.) was added, the

temperature rising to 92 C, then a further 83 g. of 40% formaldehyde solution,

which caused a further rise to 95 C. No solid remained at this stage. After

heating at 95 C for a further 5 minutes the solution crystallized

spontaneously. The mixture was maintained at 95 C for one hour, cooled to 20 C and the sodium embonate filtered and

washed with saturated brine (125 ml.).

the damp sodium embonate (about 1.2 kg.) could be used as such or

converted to the acid by dissolving in a mixture of water (3 l.) and acetone

(700 ml.), by heating to 50 C and adding glacial acetic acid (225 ml.) and then

concentrated hydrochloric acid (about 200 ml.) until the mixture was acid to

Congo red.

The precipitated embonic acid (480 g.) was

filtered, washed with hot water until free of chloride, and dried at 100 C.”

The above-noted paper by Barbier and Gaimster

provides other useful information. It teaches that a solution of sodium

embonate can readily be prepared by dissolving embonic acid in an aqueous

solution of sodium hydroxide and although the equilibrium solubility of sodium

embonate in water at 20 C is less than 10%, the solution readily supersaturates

and stronger solutions can easily be prepared.

The salts with thiamine and pyridoxine are formed as follows.

US2397903

Thiamine

Example I.- To a solution of 17 parts of thiamine

hydrochloride in 200 parts of water was added, with agitation and at room

temperature, a solution of 25 parts of the di-sodium salt of

methylene-bis-2-hydroxy-3-naphthoic acid (?% pure). A cream-colored precipitate, which on

standing partly crystallized, formed.

After recrystallization from 70% ethanol, a product, which decomposed at

180-185 C, was obtained. The yield was almost theoretical. The product had a

biological potency equivalent to the thiamine and may be termed

thiamine-methylene-bis-2-hydroxy-3-naphthoate.

Pyridoxine

Example II.

To a solution of 41.1 parts of

pyridoxine hydrochloride in 500 parts of water was added with agitation and at

room temperature, 43.2 parts of the disodium salt of methylene-bis-2-hydroxy-3-naphthoic

acid. An amorphous precipitate, which on standing partly crystallized, formed.

It was recrystallized from acetone. On heating, it decomposed. It was a little

more soluble in water than the product of Example I. It was soluble in aqueous

ethanol and acetone. It had a biological potency equivalent to the pyridoxine

hydrochloride.

There are other examples from other patents.

WO9425460A1

Risperidone

Example I

A solution of 3- [2- [4-(6-fluoro-

1,2-benzisoxazol-3-yl)- I-piperidinyl) ethyl]

-6,7,8,9-tetrahydro-2-methyl-4H-Pyrido[1,2-ajpyrimidin-4-one,19.70 g (0.

048mol) in ethanol (600ml) was added to a solution 18.64 g of pamoic acid (0.

048mol) in N,N-dimethylformamide (400ml). (1g/22 ml )

The mixture was stirred for 3 hours. The resulting precipitate was filtered off

by suction, washed with ethanol and dried, yielding 3 1 g (8.1 %) of

3-[2-[4-(6-fluoro- 1,2benzisoxazol-3-yl)- I -piperidinyl)ethyl)

-6,7,8,9-tetrahydro-2-methyl-4H-pyfido[ 1, 2ajpyrimidin-4-one

4,4'-methylenebis[3-hydroxy-2-naphthalenecarboxylate) (1: 1); mp. 269.2'C.

This

is a very poor yield of salt; just 8.1%.

Pamoic acid apparently is soluble in dimethylformamide. This is useful

information. The risperidone was dissolved in the usual ethanol. Perhaps the experimentalist did not wait long

enough for the solid to all precipitate. They filtered after 3 hours.

WO05016261A2

Haloperidol

and Aripiprazole

Example

1:

The pamoate salt of haloperidol can be prepared by treatment of haloperidol

with pamoic acid or pamoate salt in solvent. Haloperidol pamoate can be

prepared by adding a solution of haloperidol in an appropriate solvent, ea.

ethanol with acetic acid, to a solution of disodium pamoate, pamoic acid or

other pamoate salt and leaving undisturbed for 1-3 or more days until

precipitation. Alternatively, other methods such as evaporation, slow or fast

cooling or stirring solutions can also be used to precipitate salt.

Specifically, 2.5 ml of a 0.1M solution of haloperidol in an acidified ethanol

(5% acetic acid) was added to 2.5 ml of a 0.1M solution of disodium pamoate

(2.5ml) in ethanol/water (50/50 v/v). The mixture was allowed to sit at room

temperature for 1-3 days. The resulting precipitate was filtered off by

suction, washed with ethanol and dried in a vacuum oven at 60°C, yielding 240 mg

of 1:1 haloperidol pamoate salt.

Example 2:

2.5 ml of a 0.25M solution of haloperidol in an acidified ethanol (5% acetic acid) was added to 12.5 ml of a 0.05M solution of disodium pamoate in ethanol/water (75/25). The mixture was allowed to sit at room temperature for 1-3 days. The resulting precipitate was filtered off by suction, washed with ethanol and dried in a vacuum oven at 60°C, yielding 206mg of 2:1 haloperidol pamoate salt

Example 3:

2.5 ml of a 0.25M solution of haloperidol in

an acidified ethanol (5% acetic acid) was added to 6.25 ml of a O.1M solution

of disodium pamoate in ethanol/water (50/50). The mixture was allowed to sit at

room temperature for 1-3 days. The resulting precipitate was filtered off by

suction, washed with ethanol and dried in a vacuum oven at 60°C, yielding 264mg

of 2:1 haloperidol pamoate salt. - 1 1

Example 4:

ml of a 0.05M solution of haloperidol in

an acidified ethanol (5% acetic acid) was added to 1 ml of a 0.25M solution of

disodium pamoate in ethanol/water (50/50). The mixture was allowed to sit at

room temperature for 1-3 days. The resulting precipitate was filtered off by

suction, washed with ethanol and dried in a vacuum oven at 60°C, yielding 107

mg of 1:1 haloperidol pamoate salt.

Example 5:

5.ml of a 0.05M solution

of haloperidol in an acidified ethanol (5% acetic acid) was added to 2.5 ml of

a O.1M solution of disodium pamoate in ethanol/water (50/50). The mixture was

allowed to sit at room temperature for 1-3 days. The resulting precipitate was

filtered off by suction, washed with ethanol and dried in a vacuum oven at

60°C, yielding 119 mg of 1:1 haloperidol pamoate salt.

Example 6:

A (0.05 - 0.5M) solution of aripiprazole

in an acidified ethanol is added to a (0.05 - 0.5M) disodium pamoate solution

in a mixture of water/ethanol (100/0 0/100). The mixture is allowed to sit at

room temperature for 1-3 days. The resulting precipitate is filtered off by

suction, washed with solvent and dried in a vacuum oven at 60°C.

These

methods teach the method of adding the base acidified with 5% acetic acid in

ethanol to the disodium pamoate in ethanol/water. The disodium salt is more soluble and so this

method depends upon the acidification of sodium pamoate with acetic acid to

create the pamoic acid in situ where it can interact with the amine in the

presence of acetic acid. The more

insoluble amine pamoate crystallizes.

These examples illustrate the fact that pamoates often must be allowed

to change form from a gel like form to crystalline over some time. Heating sometimes accelerates this change.

WO04017970A1

AGN-2979

(C)

Preparation of 3-(3-methoxyphenyl)-3-(3-

dimethylaminopropyl]-4,4-dimethyl-piperidine-2,6-dione pamoate salt (anhydrous)

A solution of AGN-2979 bisulphate salt

obtained in Step B (1 mmole, 430 mg) in 10 ml of water was mixed with methylene

chloride (20 ml) and basified with aqueous ammonium hydroxide (29% w/w). After

separation of the layers, the aqueous phase was extracted twice with methylene

chloride. The combined organic phases were dried over anhydrous magnesium

sulphate and the solvent was evaporated under reduced pressure. The residue was

dissolved in ethanol (10 ml) and mixed with a hot solution of pamoic acid

(embonic acid, 390 mg,1 mmole) in hot ethanol (30 ml) and the mixture was

heated to reflux. After cooling, the pamoate salt crystallised and the salt was

recrystallised in hot ethanol to give a pale yellow powder (melting point =

146°-150°C.

The

procedure separates free base, evaporates to an oil and dissolves it in

ethanol. It is mixed with a hot solution of pamoic acid dissolved in hot

ethanol. The embonate came out in

crystalline form on cooling. This could be useful to effect isolation of a base that should be solid but refuses to solidify for crystallization. It can be first converted to a solid embonate and then back to a purer free base.

WO05075454A2

FORMS

OF

4-(4-METHYLPIPERAZIN-1-YLMETHYL)-n-[4-METHYL-3-(4-PYRIDIN-3-YL)PYRIMIDIN-2-YLAMINO)PHENYL]-BENZAMIDE

- IMATINIB

Example 10

4.l(4-Methyl-1

-piperazinyl)methyl]-N-[4-methyl-3-[ [4-(3-pyridinyl)-2-

pyrimidinyl]amino]phenyl]- benzamide, pamoate

A

mixture of 4-[(4-methyl-1- piperazinyl)

methyl]-N-[4-methyl-3-[[4-(3-pyridinyl)-2- pyrimidinyl]amino] phenyl]-benzamide

(4.94 g, 10 mmol) and 4,4'-methylenebis[3-hydroxy-2- naphthoic acid (Fluke,

Buchs, Switzerland; 3.88 g, 10 mmol) in ethanol (50 mL) is heated.

Water (25 mL) is then added. Upon cooling, the product crystallizes and is

filtered-off and dried to afford 4-[(4-methyl-1- piperazinyl)methyl]-N-

[4-methyl-3-[[4-(3-pyridinyl)- 2- pyrimidinyl]amino]phenyl]-benzemide, pamoate

as a pale- yellow solid, having the following analytical properties: Analysis

found: C, 69.12; H. 5.62; N. 10.88%; H2O, 2.50%. Calculated for C52H47N7O7-

1.26 H2O: C, 69.04; H. 5.52; N. 10.84%; H2O, 2. 51%.

Heating

pamoic acid in ethanol will create some solubility. The solids must have

dissolved since the addition of water is usually done to the point of turbidity

and then the crystals allowed to come out as the solution cools.

WO05012233A1

MELDONIUM

SALTS, METHOD OF THEIR PREPARATION AND PHARMACEUTICAL COMPOSITION ON THEIR

BASIS (CH3)3N+-NHCH2CH2COOH

X-

EXAMPLE

10

Meldonium pamoate (1:1; x H20). Meldoniurn (5.46 g, 30 mmol) and pamoic acid

(5.82 g, 15 mmol) are mixed with water and acetone (15 ml), the formed

suspension is evaporated, 30-40 ml toluene is added to the residual viscous

mass, it is grated, and evaporation is repeated. If the residue is

insufficiently dry, treatment with toluene is repeated. Mp. 128-133°C

(decomp.). H NMR spectrum (DMSO-d6), 6, ppm: 2.41 (2H, t, CH2COO-); 3.14 (2H,

t, CH2N); 3.25 (9H, s, Me3N+); 4.75 (2H, s, -CH=(pam)) , 7.12 (2H, t, Harom);

7.26 (2H, td, Harom); 7.77 (2H, d, Harom); 8.18 (2H, d, Harom); 8.35 (2H, s,

Harom). Found, %: C 62,90; H 5,83; N 4,98. Calculated, %: C 63,07; H S,84; N

5,07. Initially H:O content in the sample was 1.71%; after 24 hours maintenance

at 100% humidity sample mass increased by 9% due to absorbed water.

Pamoic

acid is not particularly soluble in either water or acetone. Evaporation would readily remove the acetone.

The water would only be grudgingly removed as an azeotrope with toluene.

WO0008016A1

PAROXETINE

SALTS

Example

32 : Preparation of paroxetine pamoate 1: 1 salt.

A solution of paroxetine base in toluene

(5 ml, 2. 10 g) was added to a solution of pamoic acid (2.48 g) in pyridine (40

ml), and the mixture was stirred at ambient temperature for 30 minutes. The

solvent was then removed by distillation at reduced pressure, the residual oil

diluted with toluene (30 ml) and the solvent again removed by distillation at

reduced pressure. This procedure was repeated two more times. The solid product

was washed with hot diethylether (c. 100 ml x 3) , and filtered under nitrogen

to give a pale yellow solid. The product was washed twice more with diethylether (2 x 100 n- A), and then with methanol (30 ml), and finally dried under

vacuum.

Yield = 3.27 g,

IR nujol mull:

Bands at 1636, 1558, 1508, 1459, 1377,

1183, 1036, 830, 722 CM-1.

Example 33 : Preparation of paroxetine pamoate

2:1 salt

.

A solution of paroxetine base in toluene

(10 ml, 4.2 g) was added to a solution of pamoic acid (2.48 g) in pyridine (40

ml). The mixture was stirred at ambient temperature for 30 minutes. The solvent

was then removed by distillation at reduced pressure, the residual oil diluted

with toluene (30 ml) and the solvent again removed by distillation at reduced

pressure. This procedure was repeated two more times. The solid product was

washed with diethyl ether (c. 50 ml), and filtered under nitrogen to give a

white solid. This solid was washed twice more with diethyl ether (2 x 10 ml),

and then dried under vacuum.

Yield 6.7 g.

IR nujol mull:

Bands at 1641, 1461, 13 77, 1181, 1035,

829, 757 cm- 1.

Pamoic

acid is soluble in pyridine presumably as a pyridinium salt. It can be

recrystallized from dilute aqueous pyridine.

It is also soluble in nitrobenzene.

Embonic

acid has been used to precipitate amines from a heterogeneous natural product

extract or from reaction mixtures, which may contain considerable quantities of

unwanted organic matter as well as inorganic salts. When htis is the case,

Barber & Gaimster recommend that the crystallization of the embonates can

often be facilitated by the addition of acetone, to the extent of 10 to 15% of

the total volume.

Molecules

2007, 121313

Extraction

and precipitation of alkaloid-embonates

Homogenous

dried leaves of a registered Finnish variety of C. roseus (1.0 g) were

extracted for 30minutes with 0.1 M hydrochloric acid solution (100 mL) in an

ultrasonic bath (USF Finnsonic W 181, Ultra Sonic Finland). The mixture was

then centrifuged at 2000 rpm for 10 min and the sediment wasre-extracted with

additional HCl (100 mL) for another 30 minutes. The combined supernatant from

two repeated extractions was filtered and extracted with petroleum ether (200

mL) to eliminate chlorophyll and other lipophilic compounds. The acidic

fraction was separated and an alkaline solution (pH 10.5) of 10 % embonic acid

was slowly added for the precipitation of alkaloids as their embonate

complexes. The pH of the resultant solution was increased to 5.0. The

precipitate was separated simply by decantation and it was used as starting

material for the semi-synthesis.

Based

on the forgoing information, Kilomentor would like to suggest that a basic

process intermediate could be highly likely to be precipitated either (i) from

a reaction mixture simply by the addition of a hot ethanolic solution of

embonic acid or (ii) from the aqueous acid extract of the reaction mixture by

the addition of a solution of sodium embonate.

Higher molecular weight amines are generally more likely to precipitate

than those of lower molecular weight and dibasic molecules are more likely to

precipitate than monobasic ones.

The

methodology could also possibly be used to recover reagents tagged with basic

amino groups by extracting them from neutral reaction mixtures and then

precipitating the embonates of the reagents, thus recovering them for

recycling. If it were to turn out that the corresponding embonate salts were

insoluble, one can imagine using this method to recover such useful but

expensive basic reagents as diazabicyclooctane (DABCO), diazabicyclononane

(DBN), diazabicycloundecane (DBU) tetramethylethylenediamine, ethyl

dicyclohexylamine, ethyl diisopropylamine, tributylamine,

tris(2-hydroxypropyl)amine, 2,2,6,6-tetramethylpiperidine,

1,2,2,6,6-pentamethylpiperidine, tetramethylguanidine,

1,8-bis-dimethylamno-naphthalene, dicyclohexylamine, ethyl

3,3-dimethylaminopropylcarbodiimide.

Cationic

phase transfer catalysts could possibly be recovered as insoluble

embonates.

The

reagent N-benzyl-N,N-dimethylaniline hydroxide is used to benzylate free

carboxylics by refluxing in a high boiling solvent to give the benzyl ester and

dimethylaniline. The reagent is presently prepare by treating

N-benzyl-N,N-dimethylaniline halide with silver oxide. It would seem to be less

expensive and more convenient to precipitate the embonate and cleave it with

sodium hydroxide.

The

article by Barber and Gaimster, J. appl. Chem.,2, October, 1952. teaches another

easily synthesized diacid structure that can give highly insoluble salts. This

new acid , 2:2’-dihydroxy-1:1’-dinaphthyl-3:3’-dicarboxylic acid. It differs

from embonic acid in that the single methylene, which connects the two naphthyl

groups in embonic acid has been replaced by a direct connection between the

rings.

The

compound is made according to the following procedure”

2-Hydroxy-3-naphthoic

acid (18.8g.) was dissolved in a solution of sodium hydroxide (8 g.) in water

(580 ml.) and the solution was refluxed while a solution of ferric chloride (23

g. of the hexahydrate) and concentrated hydrochloric acid (26 ml) in water (29

ml.) was added drop-wise with strong stirring during 30 minutes, then cooled,

filtered and the filtrate rejected. After washing with a little water, the

residue was dissolved in a slight excess of N-sodium hydroxide solution (about

200 ml.). The solution was treed with charcoal, filtered, acidified with

concentrated hydrochloric acid and filtered.

The yellow residue, after washing with water, was recrystallized from

aqueous ethanol to give 2.8 g. , 2:2’-dihydroxy-1:1’-dinaphthyl-3:3’-dicarboxylic

acid as a pale-yellow hemihydrate, mp 330-333 C.