General schemes have been devised for examining unknown mixtures such as those one learns as an undergraduate chemist for a laboratory examination. Such schemes as those in the classic text by Shriner, Fuson, and Curtin. [The Systematic Identification of Organic Compounds: A Laboratory Manual. Fifth Edition John Wiley & Son 1964] The more complex of these schemes, no matter what their wisdom, have never to my knowledge been adopted by real chemists to work up real reaction mixtures. The reason is simple. These schemes are designed to handle complete unknowns. The bench chemist always knows something about his mixture, even if it is no more than the fervent hope that a particular product will be present; therefore, the working chemist or chemical engineer is in a more knowledgeable position and so the protocol for a complete unknown is going to be inefficient.

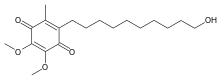

Since at least the functional groups and molecular weight of the desired product are known and so some educated guesses can be made about the likely physical properties and a theoretical proposal can be made for a rational separation. For example, if the hoped-for product is a neutral lipophilic aldehyde, a mild aq. acid extraction and a mild aq. base extraction can be applied to an ether solution. Then some aldehyde-specific reagents such as bisulfite or Girard’s P or T can be contemplated.

Another reason that these classical schemes are set aside is that they apply solubility tests in unappealing solvents such as carbon tetrachloride and benzene. Today these are unacceptably toxic solvents.

What would be more interesting and have more likelihood of application would be a scheme, that could be adapted to take account of predicted estimated properties of a particular reaction mixture and would have an inherent awareness of the most helpful procedures for separations at scale.

To explore this, let us assume first that at the end of the reaction period, the reactor content is homogeneous and the TLC or other in-process check is encouraging. Let us also assume that the trial reaction has been conducted on a scale of at least several grams. I make this assumption first because improving the throughput in a series of reactions in a process scheme should focus on the early steps and these are intended to be the ones using the less expensive materials.

If the content is not homogeneous, the phases should be separated and treated separately. This practice is based on the wise rule that the chemist should never immediately refuse a phase separation offered by nature while exploring further manipulations. If there is a solid in a liquid, filter the solid and retain the filtrate. If there are two liquids, cut the phases and examine each. Such natural separations are not likely to be quantitative recoveries of any component, but the constitution of the phases may provide a guide to a modification that can deliver a more complete separation.

Supposing in the alternative now that the phase is a single one or that we are examining multiple phases separately, the chemist will be fairly confident that the main constituent of this phase is solvent and the solvent is the reaction solvent. The first step will be to remove that solvent completely without exposing the other constituents to conditions so severe that they may resume reacting with each other. The chemist is the best judge of how to achieve this and how to make sure that no further chemical reaction happens.

Let us therefore suppose now that the solvent has been removed under mild conditions and the residue, either as an oil, a mixture of solids and liquids, or a glass is available to be examined.

It is not possible to separate effectively a viscous oil from a solid. In this situation, oil and solid probably must be handled together although again this is a situation where the chemist’s powers of observation and judgment are more useful than any strict rule.

The mixture should be examined for its solubility properties much as in the classic approach in Shriner, Fuson, and Curtin but the solvents should be different and be based on a different principle.

The solvents, which might be used are hexane, acetonitrile, methanol, and ethyl ether. The first three solvents are chosen because methanol and hexane in the presence of a few percent of water give two immiscible phases and the same is true of acetonitrile and hexane. Different solubility information among these three can not only direct us to a trituration step but differential partitioning among these pairs can identify liquid-liquid extraction possibilities.

Although diethyl ether is not a solvent acceptable in a general-purpose chemical plant, its remarkable ability to avoid forming emulsions makes it irreplaceable for acid and basic aqueous extraction tests.

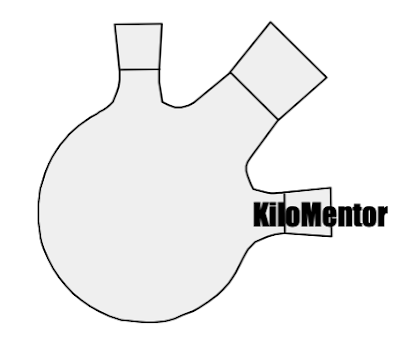

So in practice, one gram of the mixture is placed in a small r.b. flask treated with 7 ml of methanol and swirled. If any solid remains undissolved the slurry can be cooled in ice to maximize the quantity of solid and filtered cold and washed with a little cold methanol. Such solid is examined.

If there is no solid in the solution we could add 7 ml/gm of hexane(s) and mix the phases together. Again we look for any solid, which might separate and treat it appropriately. If two immiscible liquid layers are not present a drop or two of water is added to make the methanol layer separate. The two phases are separated and each is evaporated to dryness, pumped under vacuum, and weighed. Each phase should be examined, if it is convenient, by the same analysis that was used for the reaction’s in-process check. The combination of the weights obtained and the analyses of the separate layers are useful properties of the mixture. They may provide the first hints of the most efficient methods of isolation. If one phase or the other contains essentially all the contents of the mixture all one can say is that the mixture is substantially polar or apolar, depending on to which solvent the mixture components have migrated.

If the mixture is substantially apolar take a new sample of the mixture in a small r.b. flask and tread it with 7 ml of acetonitrile and swirl, repeating the procedure that was used with methanol. In the case of acetonitrile, water will very rarely be needed to get two liquid phases upon adding hexane. In fact, try to avoid using water here. The two phases are separated and each is evaporated to dryness, pumped under vacuum, and weighed. Each phase should be examined, if it is convenient, by the analysis that was used for the reaction’s in-process check. The combination of the weights obtained and the analyses of the separate layers again are useful properties of the mixture. They may provide the first hints at the most efficient methods of isolation. If one phase or the other contains essentially all the contents of the mixture all one can say is that the mixture is substantially polar or apolar.

Water is not used in these tests. Nevertheless, there is a good likelihood that if an inorganic salt is present it will be insoluble in one of methanol or acetonitrile and will have been filtered off.

A frequent result of this work will be that the substantial majority of the reaction mixture will remain in the hexane layer. This is to be expected since the vast majority of organic compounds are substantially lipophilic and noncrystalline when present as mixtures; nevertheless, when a useful separation is made at this stage it may be particularly useful for its simplicity.

Take a new portion of the mixture and try to dissolve it in 7 ml/g of diethyl ether. Again if there is a solid separate it. Now, classically extract the diethyl ether with an equal volume of 1N aq. HCl and separate the phases. Adjust the pH of the aqueous phase back to neutrality observing any cloudiness or solid separation and then back extract the murky neutralized water with ether, dry, evaporate to dryness, and weight.

In the same classical fashion extract the ether, which has been acid extracted with aq. base of pH about 9.0 and recovery the acid fraction.

Recover the neutral constituents from the residual ether. That has now been treated both with aq. acid and aq. base.

Each phase should be examined if it is convenient by the analysis that was used for the reaction’s in-process check. The combination of the weights obtained and the analyses of the separated layers are useful properties of the mixture.

Quite often very little more will have been accomplished than would have been achieved following the tried and true rules of thumb, but a useful number of times something really exciting and simplifying will have been drawn to your attention.

If the material, that you are seeking is either in the acidic or the basic fractions, even if it is still a serious mixture, your problems are well on their way to resolution because the means for rugged separations of such mixtures at scale are plentiful, and these methods I explore elsewhere. See for example Kilomentor’s blog on extractive crystallization.

If the substance you are seeking still seems only to be found in the hexane or neutral diethyl ether phases more sophisticated means need to be applied. If 30% or more of a target substance has ended up in the methanol or acetonitrile phases there is reason to hope that more intensive extractions may give you what you need.

If TLC of the methanol, acetonitrile, or hexane solutions showed a substantial amount of material remaining at the origin, the presence of high molecular weight or even polymeric materials is likely. If the mixture is strongly colored and the product sought is not expected to show color, polymer and tars are likely and the mixture should at the outset be cleaned up before looking for the desired species. Filtering through a plug of adsorbent, which retains the origin material is usually successful. Charcoaling a portion in an alcohol solvent often works. Sometimes steam distillation, regular distillation, or codistillation with a high boiling hydrocarbon can be useful. In codistillation, with kerosene be mindful that you will need to get the mixture back from the high boiling solvent!

Because cyclohexane combined with nitromethane or nitroethane, or any mixture of the two, also forms two immiscible phases; the same methods illustrated above can be applied in this system. The same goes apparently with cyclohexane and mixtures of dimethylformamide/dimethylacetamide. With these combinations, the temperature needs to be kept not too far above ambient to preserve the two-phase behavior.

Hydrotropes can also be used to dissolve components of an unknown mixture into water.